The so far existing designs of the established CASTOR® types and especially its fuel baskets for the spent-fuel assemblies (FA) were mainly driven by extreme boundaries and requirements in GNS´ German home market. The larger geometric dimensions of the German FA and higher burnups in typical German NPPs in combination with requested short cooling times, limited the number of FA per cask. This limitation is very much in contrast to the internationally increasing demand for storage systems with larger capacities in terms of accommodated FA per cask.

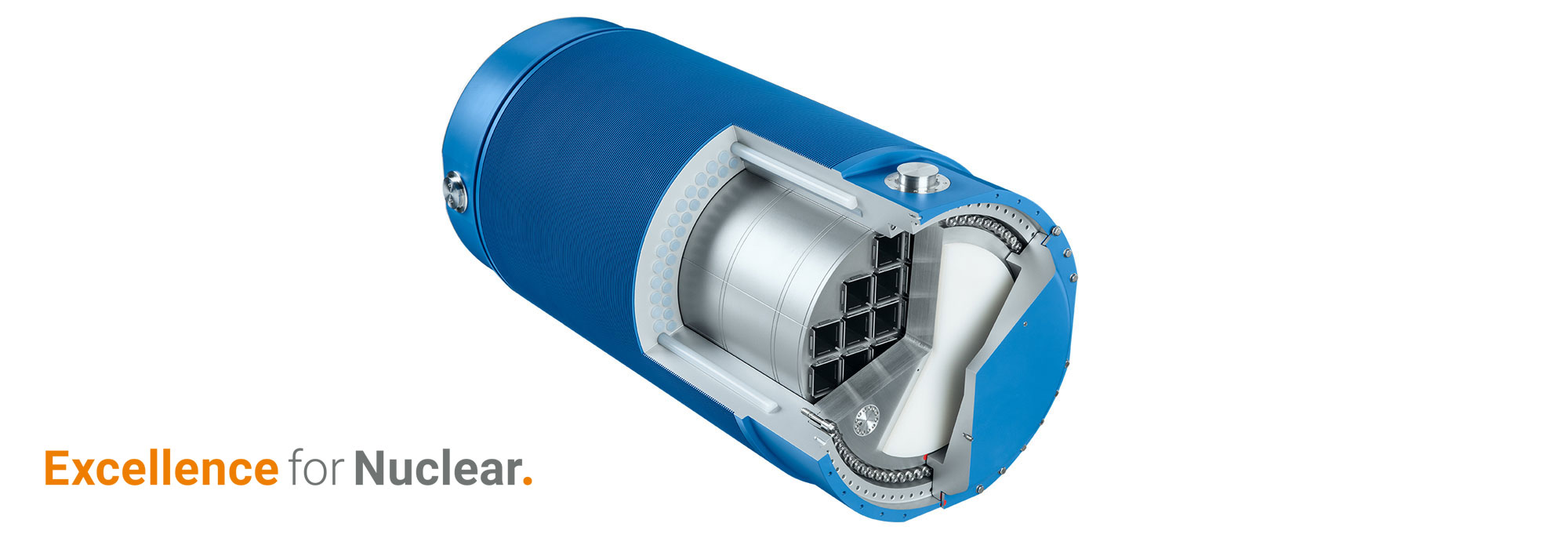

Facing the challenge of the demand of higher FA capacities per cask, GNS developed a new transport and storage system, the CASTOR® geo. The CASTOR® geo includes all the well known and established safety features of the existing CASTOR® systems, while it is able to accommodate a significantly higher number of FA per cask.

CASTOR® geo casks are able to accommodate up to 37 PWR-FA or 69 BWR-FA respectively with a maximum initial enrichment of approx. 5 wt-% 235U, up to 74 GWd/MTU average burn-up and more than 40 KW heat load. Options for the dry storage of MOX fuel are also available.

The operator of the Belgian NPPs Doel and Tihange have signed a contract with GNS for the development, licensing, and manufacturing of 30 transport and storage casks of the type CASTOR® geo24B and CASTOR® geo21B. The contract also includes the option for further casks to serve the future demand for storage casks until 2030.

The first CASTOR® geo24B has been loaded at Doel NPP in July 2024.

A nuclear power plant from Switzerland has signed a contract with GNS to deliver up to 51 casks of the type CASTOR® geo32CH.