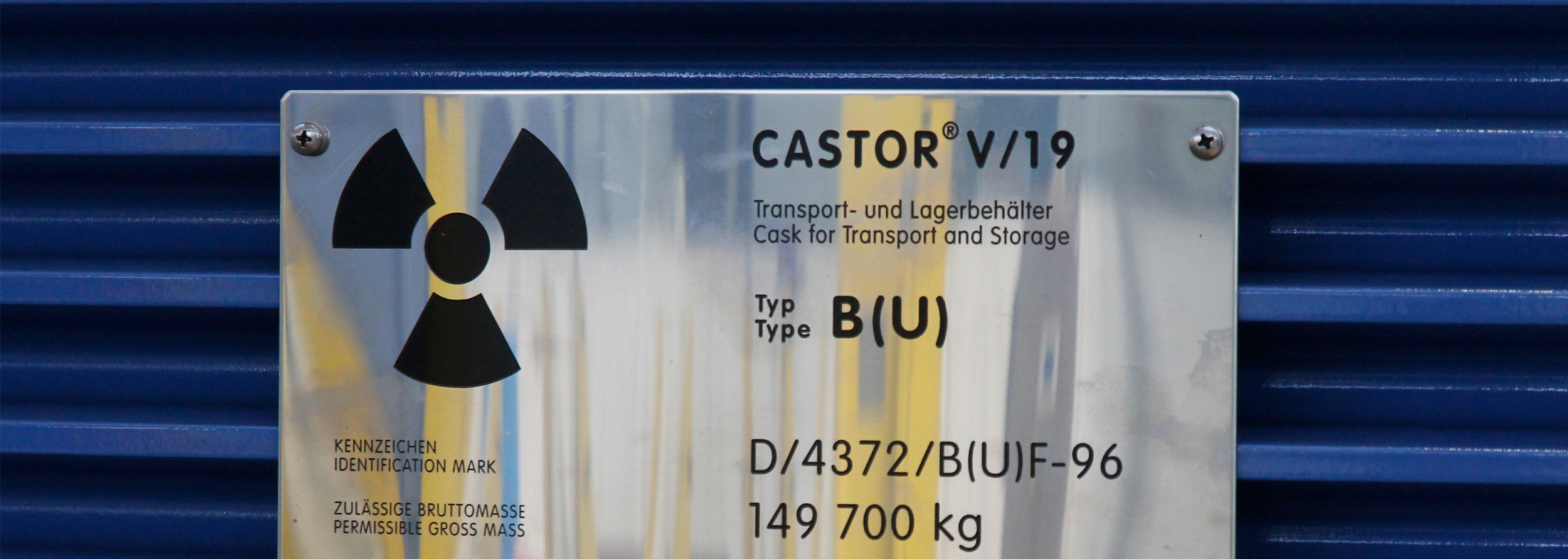

The casks of the CASTOR® V series are the most widely used CASTOR® casks. More than 750 of them have already been loaded with used fuel elements in the nuclear power plants of German energy suppliers alone and stored in the local on-site interim storage facilities. The CASTOR® V/19 is used for pressurized water reactor fuel assemblies and the CASTOR® V/52 for boiling water reactor fuel assemblies.

The casks consist of a monolithic body made of spheroidal graphite cast iron, a basket to hold the fuel assemblies and the closure system arranged one above the other, consisting of a primary and secondary lid and a protective plate. Radial cooling fins are incorporated into the outer surface of the cask body to improve passive heat dissipation. The primary and secondary lids are made of stainless steel and are firmly bolted to the cask body. In conjunction with metal seals, they ensure the safe long-term containment of the fuel assemblies.

In the interim storage facility, the sealing system consisting of the two barriers is permanently monitored for leaks. The monitoring is carried out by a pressure switch integrated in the secondary lid. For neutron moderation, polyethylene rods are arranged in axial holes in the cask wall and polyethylene plates are arranged in the base area and on the underside of the secondary lid. Trunnions are bolted in pairs to the base and lid sides of the cask body for handling the casks. The cask can be fitted with shock absorbers for transportation on public roads.